Rotating Detonation Engines: 25% More Efficient Rockets

TL;DR: NASA's next-generation xEMU spacesuit transforms lunar exploration by enabling eight-hour workdays, full-body mobility, and accommodation of diverse astronaut body types - capabilities unimaginable during Apollo's brief moonwalks. Five decades of lessons from Apollo, Shuttle, and ISS programs deliver renewable life support, advanced materials, and ergonomic design that shift humanity from visiting the Moon to building a sustainable presence there.

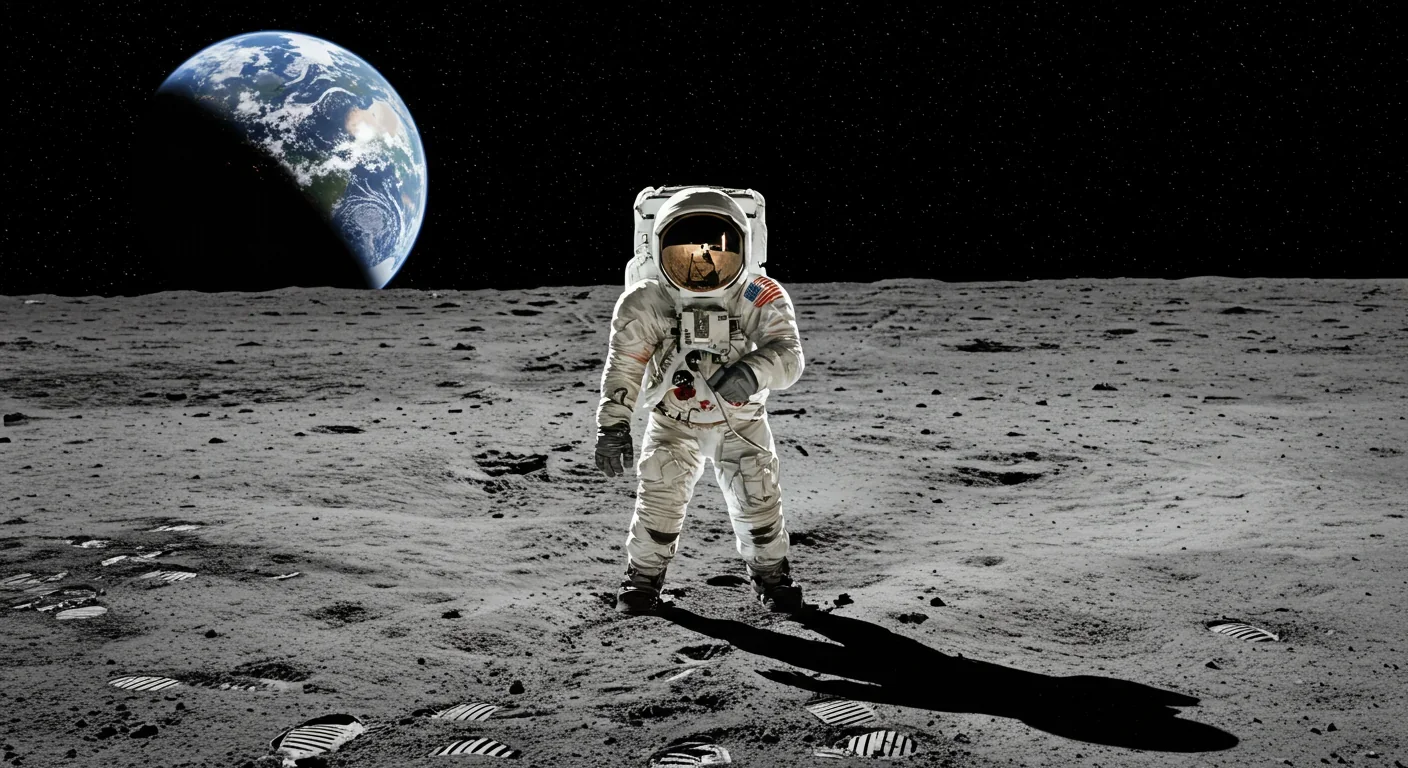

In July 1969, Neil Armstrong's first steps on the Moon represented more than a giant leap for mankind - they were a testament to the Apollo A7L spacesuit that kept him alive in one of the universe's most hostile environments. But that iconic white suit, weighing 200 pounds and allowing just six hours of lunar exploration, was never designed for the kind of sustained scientific work NASA envisions for its return to the Moon. Today, as the Artemis program prepares to land astronauts on the lunar surface for the first time in over five decades, the next-generation xEMU represents a quantum leap in protection, mobility, and capability. This isn't just about walking on the Moon anymore - it's about building a sustainable human presence there.

The transformation from Apollo to Artemis reflects five decades of lessons learned, technological breakthroughs, and a fundamental reimagining of what astronauts need to accomplish on the lunar surface. Where Apollo astronauts struggled with rigid joints and limited flexibility, their Artemis counterparts will bend, kneel, and work with unprecedented freedom. Where Apollo's life support systems imposed strict time limits, xEMU promises eight-hour workdays with emergency extensions. The evolution tells a story not just of engineering progress, but of humanity's growing ambition in space.

The A7L spacesuit was a marvel of 1960s engineering, but it was built under immense time pressure and with limited understanding of lunar conditions. Its designers faced a brutal trilemma: protection, mobility, or weight - pick two. The suit they delivered protected astronauts admirably but left them struggling with basic tasks. Armstrong himself noted in his technical debriefing that gloves made fine manipulation nearly impossible, and the suit's rigidity prevented astronauts from fully kneeling or bending at the waist.

The A7L's front-entry design, while innovative for its time, created significant ergonomic challenges. Astronauts had to contort themselves through a vertical zipper running down the back and around the crotch, a process that became increasingly difficult after exhausting EVAs. The suit's shoulder bearings faced more to the left and right rather than forward, forcing unnatural arm positions that contributed to long-term shoulder injuries among astronauts - a problem that wouldn't be fully understood until years later.

Life support posed equally severe constraints. The Portable Life Support System used lithium hydroxide canisters to scrub CO₂ from breathing air, but these canisters became saturated after about six hours, creating a hard limit on EVA duration. The cooling system operated on an open loop, expelling water directly into space - simple and effective, but wasteful and incapable of extended operation. Apollo 11 through 14 missions were limited to four-hour EVAs, while later missions stretched to eight hours by carrying more consumables, adding weight that made the already cumbersome suits even more burdensome.

Apollo suits weighed 200 pounds on Earth and operated at just 3.7 psi internal pressure - a delicate balance between providing enough oxygen and maintaining enough flexibility for astronauts to move at all.

Perhaps no challenge proved more vexing than lunar dust. The fine, abrasive regolith infiltrated every seal and joint, degrading performance and creating wear problems that compromised long-term reliability. Apollo astronauts returned from moonwalks with suits coated in electrostatically charged dust that resisted all cleaning attempts. The material threatened seals, scratched visors, and even posed potential health risks when brought back into the lunar module. NASA recognized that any sustained lunar presence would require far better dust mitigation strategies.

Between Apollo's end in 1972 and Artemis's beginning in the 2020s, NASA accumulated thousands of hours of spacewalking experience through the Space Shuttle and International Space Station programs. The Extravehicular Mobility Unit (EMU) that served these missions incorporated crucial lessons from Apollo while introducing innovations that would inform xEMU's design.

The EMU's modular architecture represented a philosophical shift. Rather than custom-fitting each suit to an individual astronaut, NASA developed a system of interchangeable components that could be mixed and matched. This approach reduced costs and increased flexibility, but it also revealed persistent limitations. The front-entry design remained, and with it the shoulder injury problems. Glove dexterity improved marginally but still left astronauts with aching hands after long EVAs. Most critically, the EMU was designed for microgravity work, not the challenges of planetary surface operations.

Russia's Orlan spacesuit, in contrast, pioneered a rear-entry design that NASA engineers observed with interest. Cosmonauts literally climbed into the back of their suits through a hatch in the hard upper torso, then sealed themselves in. This approach aligned shoulder bearings naturally and made donning and doffing dramatically easier. The design choice exemplified how different engineering philosophies could solve the same problems in radically different ways.

Testing on the ISS also revealed how materials and systems aged in the space environment. Seals degraded, bearings wore, and fabrics weakened under constant exposure to vacuum, temperature extremes, and radiation. These insights proved invaluable for designing a suit meant to last through multiple lunar missions rather than a handful of short visits. The cumulative knowledge - from Apollo's pioneering efforts through decades of orbital operations - created a foundation for the most ambitious spacesuit ever attempted.

NASA's Exploration Extravehicular Mobility Unit represents a clean-sheet design informed by everything learned since the 1960s. Amy Ross, xEMU pressure garment subsystem lead, describes it as capitalizing on "lessons from Apollo, decades of EMU experience" while targeting the specific challenges of sustained lunar surface operations. The result is a suit that bears little resemblance to its predecessors beyond the basic requirement of keeping humans alive in vacuum.

The xEMU's rear-entry design, inspired by the Russian Orlan, eliminates many of Apollo's ergonomic nightmares. The machined aluminum upper torso features a hatch that allows astronauts to back into the suit and seal it closed, a process that takes minutes rather than the contortions required by front-entry suits. More importantly, the shoulder bearings cant forward, aligning with natural arm positions and eliminating the unnatural angles that caused so many injuries during Apollo and Shuttle programs.

Mobility improvements permeate every joint. The lower torso incorporates dual hip bearings with soft fabric between them, enabling natural gait movements including crouching and kneeling - movements that Apollo astronauts could only approximate with bunny hops and awkward bending. Gloves received perhaps the most attention, with new designs enabling the fine motor control necessary for operating tools, collecting samples, and performing maintenance tasks. Where Apollo astronauts complained of complete loss of fingertip sensitivity, xEMU aims for something approaching bare-handed dexterity.

"We should clear that suit so that you could go down to your knees, and we should work more on being able to do things on the surface with your hands."

- Neil Armstrong, Apollo 11 technical debriefing

The xEMU achieves this improved mobility while accommodating a far broader range of body types. Where Apollo suits were custom-fitted to individual astronauts - predominantly male and of similar builds - xEMU is designed to fit anyone from the 5th percentile female to the 95th percentile male, covering at least 90% of the potential astronaut population. This isn't just about inclusivity; it's practical logistics for a sustainable lunar program where suits must be maintained in orbit or at a lunar outpost rather than custom-built for each mission.

If mobility improvements make xEMU more capable, its life support innovations make it genuinely transformative. The Portable Life Support System has been completely reimagined around renewable rather than consumable resources, fundamentally changing the calculus of lunar surface operations.

At the heart of this transformation lies a regenerative CO₂ removal system using two amine beds. One bed constantly absorbs carbon dioxide while the other desorbs it directly to vacuum, then they switch roles in a continuous cycle. This eliminates the saturation problem that limited Apollo EVAs to six hours and required carrying heavy replacement canisters. The system can operate indefinitely as long as power remains available, making the traditional EVA duration limits obsolete.

Thermal control received similar revolutionary attention. Apollo's open-loop water cooling worked but wasted a precious resource by venting it to space. The EMU improved on this with a sublimator, but these devices proved sensitive to water quality and required separate water supplies. xEMU's Spacesuit Water Membrane Evaporator (SWME) allows cooling water to evaporate directly through a permeable membrane, avoiding contamination sensitivity while using the same water supply that circulates through the liquid cooling garment. The SWME has undergone hundreds of hours of testing and represents the kind of elegant engineering solution that seems obvious only in hindsight.

The xEMU targets eight-hour EVAs with emergency extension capability - a 33% increase over Apollo's maximum duration, enabling full workdays of scientific activity rather than rushed surface visits.

These improvements combine to create what amounts to a wearable spacecraft far more capable than Apollo's personal life support system. Power management, thermal control, atmosphere management, and communications are integrated in ways that reduce mass while increasing capability. The PLSS no longer dictates when astronauts must return to their lander; mission objectives do.

Five decades of materials science advancement manifest throughout xEMU's construction. Where Apollo relied on coated nylon and Teflon for micrometeorite protection and thermal management, modern suits employ advanced composites, high-performance fibers, and specialized coatings developed through decades of aerospace research.

The pressure garment layer - the critical barrier between astronaut and vacuum - uses materials that maintain flexibility across the Moon's extreme temperature range while providing tear resistance far superior to Apollo-era fabrics. Multiple insulation layers incorporate reflective materials and aerogel composites that offer better thermal protection at reduced thickness, contributing to improved mobility. The outer layer must resist abrasion from lunar regolith while reflecting solar radiation and providing micrometeorite protection, a combination that demands carefully engineered multilayer construction.

Bearings and seals received particular attention given their critical role in both mobility and safety. Modern bearing designs use advanced lubricants and materials that maintain performance across hundreds of pressurization cycles and extreme temperature swings. Seals must prevent air leakage while remaining flexible enough not to restrict movement - a balance that Apollo never quite perfected but that modern materials science has dramatically improved.

Dust mitigation strategies represent perhaps the most significant materials challenge. NASA researchers have developed specialized coatings and surface treatments that resist the electrostatic adhesion that made lunar dust such a problem during Apollo. Seals use geometries and materials that prevent dust infiltration even under repeated exposure. These aren't exotic laboratory materials but practical solutions ready for the harsh reality of lunar operations, where dust infiltrated every mechanism during the first Moon landings.

One of xEMU's most significant departures from Apollo isn't technological but organizational. NASA selected Axiom Space to develop the Axiom Extravehicular Mobility Unit (AxEMU) based on NASA's xEMU prototype, representing a fundamental shift from government-only development to commercial partnership.

This approach offers several advantages. Axiom can leverage NASA's extensive research - essentially decades of publicly funded R&D - while pursuing additional commercial customers to offset development costs. NASA reduces its technical and schedule risk by relying on proven commercial development practices while maintaining oversight through detailed requirements and safety standards. The model has worked well for cargo resupply and crew transport; applying it to spacesuits represents a logical extension.

"NASA's partnership with Axiom is critical to landing astronauts on the Moon and continuing American leadership in space."

- Bill Nelson, NASA Administrator

The partnership also enables innovation through competition. Multiple companies are developing spacesuit systems for NASA, each bringing different engineering approaches and technologies. This contrasts sharply with Apollo's concentrated development, where a single prime contractor worked under NASA's direct supervision. Competition theoretically drives down costs and accelerates innovation, though it also introduces coordination challenges when different suits must work together in the same environment.

Critics note that the commercial model introduces profit motives into equipment design where safety must remain paramount. NASA maintains that its oversight and certification requirements ensure safety standards won't be compromised, but the transition still represents a cultural shift. A team of 45 civil servants and 170 contractors worked on xEMU development, a ratio that reflects this new public-private dynamic.

Despite xEMU's impressive capabilities, significant challenges remain. Development costs have exceeded initial projections, and schedule delays have pushed back Artemis timelines. The Government Accountability Office has raised concerns about whether NASA's ambitious schedule can be met given the complexity of certifying new spacesuits for human use.

Testing presents particular difficulties. Unlike Apollo, which could test suits in actual lunar conditions after the first mission, xEMU must be validated entirely through Earth-based testing and brief ISS trials before astronauts depend on it during lunar EVAs. Neutral buoyancy facilities, vacuum chambers, and partial gravity simulations can only approximate lunar conditions. Some aspects simply cannot be fully validated until the first Artemis astronauts actually don the suits on the Moon.

The dust problem, while addressed through advanced materials and coatings, remains incompletely solved. Apollo astronauts dealt with dust during a handful of short visits; Artemis crews will face sustained exposure during multi-day surface stays and repeated EVAs. Whether xEMU's dust mitigation strategies prove adequate for this extended exposure won't be known until they're tested in actual lunar conditions.

Long-term maintenance and lifecycle costs remain uncertain. Unlike Apollo's disposable suits, xEMU must be maintained and reused across multiple missions, potentially at a lunar outpost with limited repair facilities.

Sizing flexibility, while dramatically improved over Apollo, still can't accommodate every possible body type. Edge cases remain where astronauts may not fit properly despite the expanded range. Glove fit proves particularly problematic, as hands vary more than body proportions in ways that challenge one-size-fits-most approaches. Getting glove fit wrong doesn't just reduce dexterity; it can cause injury during long EVAs.

xEMU's capabilities fundamentally change what's possible during lunar surface operations. Eight-hour EVAs enable serious scientific fieldwork rather than rushed sample collection. Improved mobility allows astronauts to access more varied terrain, including slopes and boulder fields that would have been dangerous or impossible in Apollo suits. Better gloves mean they can operate complex instruments, perform maintenance, and conduct experiments with far less frustration.

The ability to accommodate diverse body types expands the potential astronaut pool, bringing more perspectives and expertise to lunar exploration. Sustainable lunar presence requires a variety of skills - geologists, engineers, physicians, technicians - not just test pilots of similar physical builds. xEMU makes that diversity practically possible rather than aspirational.

Renewable life support creates operational flexibility unimaginable during Apollo. Emergency situations won't automatically become life-threatening just because an EVA runs long. Surface crews can adjust their work schedules based on mission needs rather than consumable limitations. Future lunar bases could support daily EVAs for construction and research without the logistical burden of constantly resupplying LiOH canisters and cooling water.

The lessons learned developing xEMU will inform future suit designs for Mars exploration, asteroid missions, and other destinations. The engineering principles, materials, and systems scale beyond the Moon. In that sense, xEMU represents not just Artemis's enabler but a stepping stone toward humanity's long-term future as a spacefaring species.

Comparing the A7L and xEMU reveals how far human spaceflight technology has advanced. Apollo's suit was an incredible achievement for its era, but it was also a product of intense deadline pressure and limited knowledge. Engineers worked with slide rules and nascent computer models, testing fabrics and life support systems that had never been exposed to the lunar environment.

Today's designers work with decades of flight experience, advanced computational modeling, materials that didn't exist in the 1960s, and a deep understanding of how systems perform in space. They're not starting from scratch but building on a foundation of knowledge purchased at enormous cost during the Apollo era and refined through thousands of spacewalks since.

Yet some challenges remain fundamentally unchanged. Creating a flexible pressure vessel that protects humans from vacuum without restricting movement is still a materials science and engineering puzzle. Balancing protection, mobility, and weight continues to force difficult tradeoffs. Managing heat in an environment with no atmosphere for convective cooling still requires ingenious solutions. The problems have the same core; only the tools for solving them have improved.

"Our partnership is investing in America, supporting America's workers, and demonstrating another example of America's technical ingenuity that will position NASA and the commercial space sector to compete - and win - in the 21st century."

- Bill Nelson, NASA Administrator

Armstrong's 1969 moonwalk lasted 2 hours and 31 minutes. Artemis astronauts could spend eight hours at a time exploring, working, and conducting science. That difference encapsulates what five decades of engineering progress enables. It's not that Apollo astronauts couldn't have accomplished more given time; their suits simply didn't allow it. xEMU removes that constraint.

NASA's current timeline calls for Artemis III - the first crewed lunar landing of the program - to occur in the mid-2020s, though this schedule has already slipped multiple times and remains uncertain. The Artemis program faces budget pressures, technical challenges, and political headwinds that could further delay humanity's return to the Moon.

When it does happen, those first Artemis astronauts will step onto the lunar surface in suits representing the culmination of everything learned since Apollo. They'll bend down to collect samples without strain. They'll work full shifts conducting experiments. They'll accommodate diverse body types. And they'll do it all while protected by systems that learned from five decades of experience in the ultimate hostile work environment.

The evolution from A7L to xEMU isn't just about technological improvement. It represents a maturation of human spaceflight from desperate sprint to sustainable presence, from sending test pilots on brief visits to enabling diverse crews to live and work off-world. Apollo proved humans could reach the Moon; Artemis aims to prove they can stay.

The spacesuits that enable this transformation may never achieve the iconic status of Apollo's white suits. But their capabilities represent something more important than symbolism: the practical reality of humans becoming a spacefaring species. Fifty years from now, Artemis suits may seem as primitive as Apollo suits do to us now. That progression, that continuous improvement, is how humanity expands its reach beyond a single planet.

The journey from Moon walkers to Moon builders required reimagining everything about how humans survive in space. It required learning from failures, iterating on successes, and maintaining a vision across decades when humans didn't venture beyond low Earth orbit. xEMU represents that vision realized: not just better engineering, but a commitment to making space accessible enough that humans can do more than visit. They can work. They can build. They can stay.

That's the real evolution these spacesuits enable - not better technology for its own sake, but better technology that allows humanity to do what Apollo could only hint at. The difference between a 2-hour moonwalk and an 8-hour workday is the difference between tourism and settlement, between flags and footprints and permanent human presence. That difference is what five decades of spacesuit evolution has purchased, and it may prove to be one of the most important technological advances in human history.

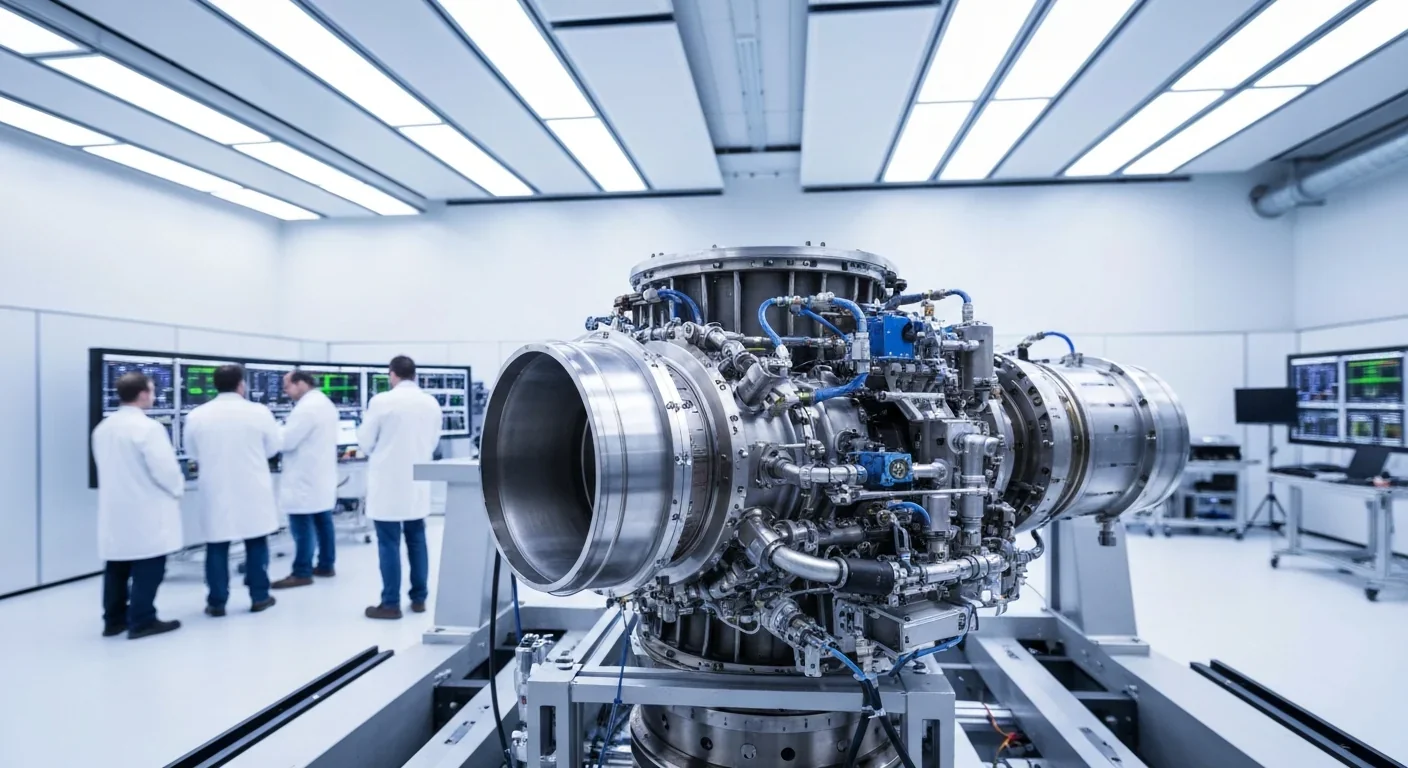

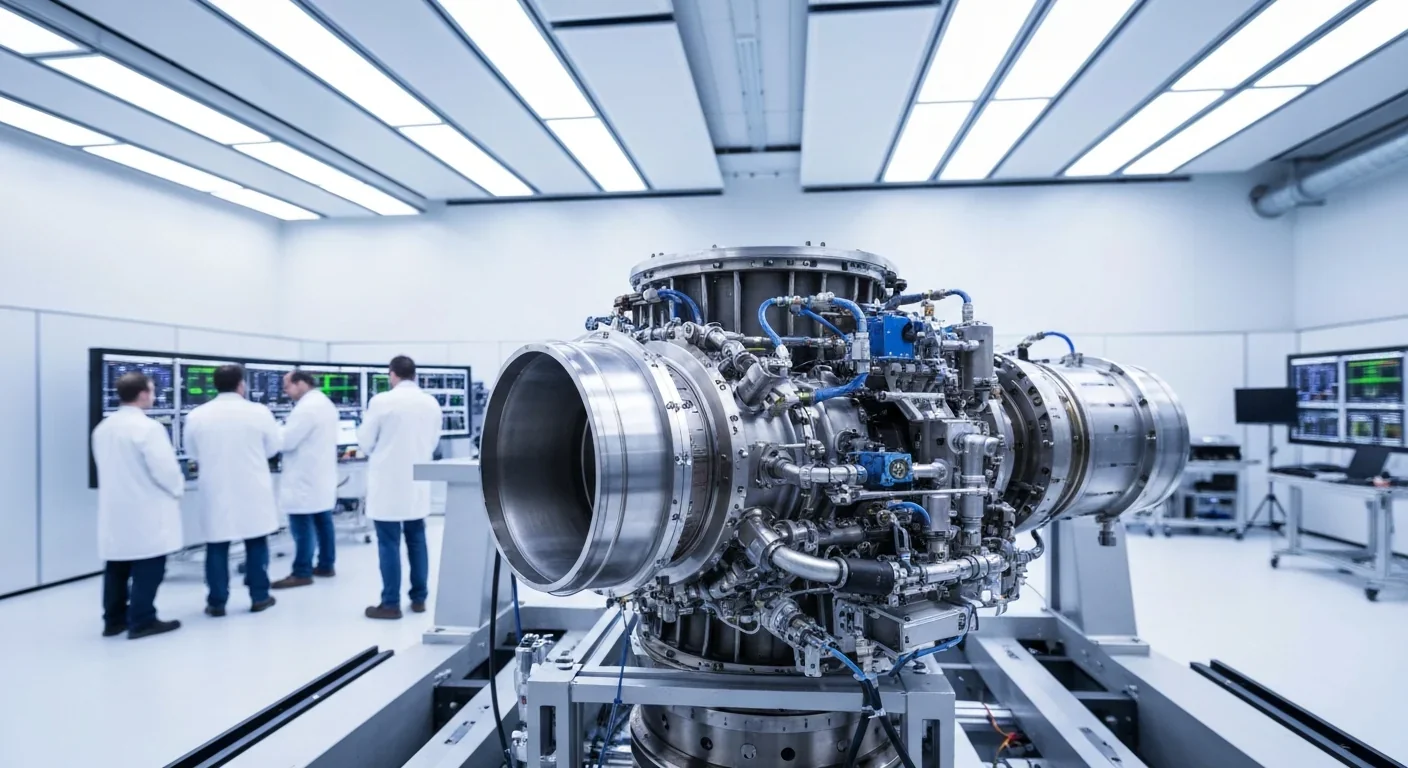

Rotating detonation engines use continuous supersonic explosions to achieve 25% better fuel efficiency than conventional rockets. NASA, the Air Force, and private companies are now testing this breakthrough technology in flight, promising to dramatically reduce space launch costs and enable more ambitious missions.

Triclosan, found in many antibacterial products, is reactivated by gut bacteria and triggers inflammation, contributes to antibiotic resistance, and disrupts hormonal systems - but plain soap and water work just as effectively without the harm.

AI-powered cameras and LED systems are revolutionizing sea turtle conservation by enabling fishing nets to detect and release endangered species in real-time, achieving up to 90% bycatch reduction while maintaining profitable shrimp operations through technology that balances environmental protection with economic viability.

The pratfall effect shows that highly competent people become more likable after making small mistakes, but only if they've already proven their capability. Understanding when vulnerability helps versus hurts can transform how we connect with others.

Leafcutter ants have practiced sustainable agriculture for 50 million years, cultivating fungus crops through specialized worker castes, sophisticated waste management, and mutualistic relationships that offer lessons for human farming systems facing climate challenges.

Gig economy platforms systematically manipulate wage calculations through algorithmic time rounding, silently transferring billions from workers to corporations. While outdated labor laws permit this, European regulations and worker-led audits offer hope for transparency and fair compensation.

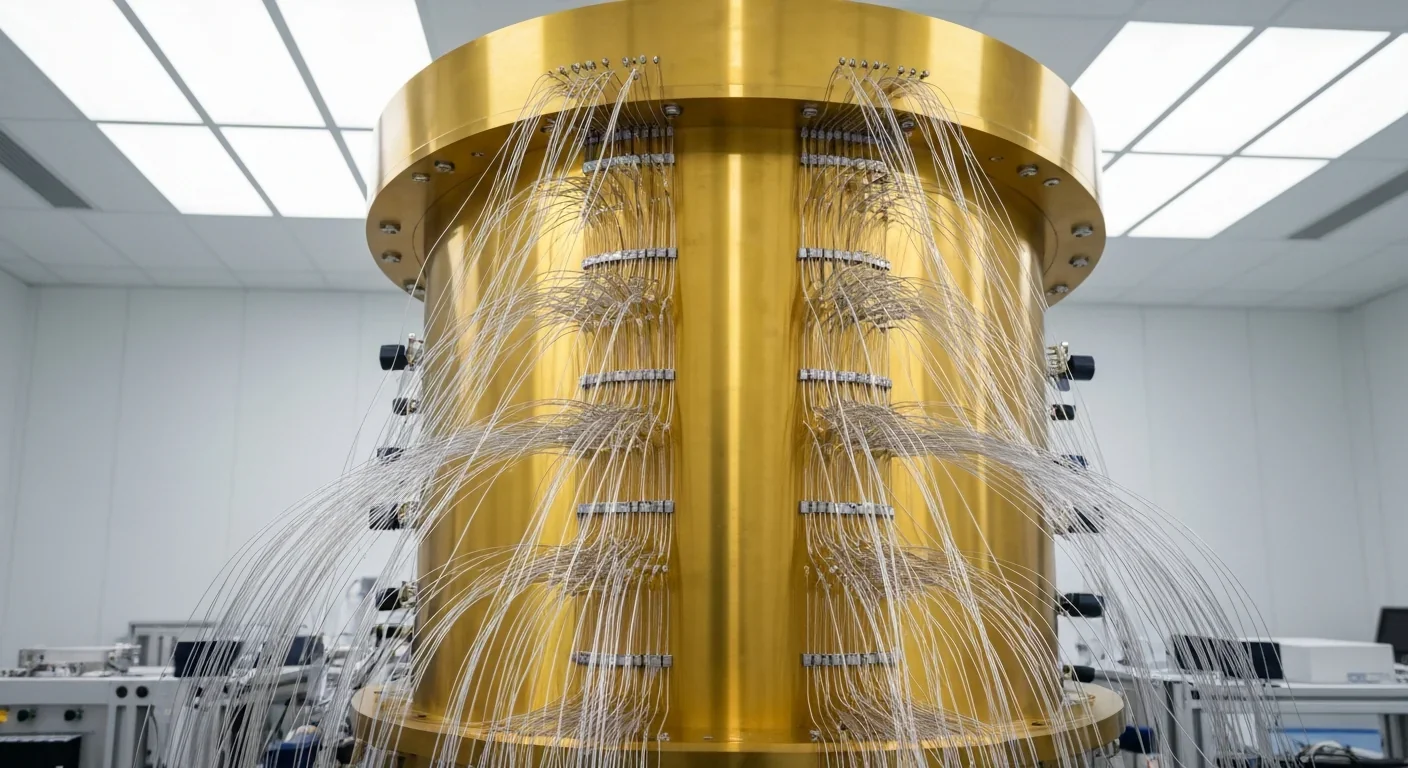

Quantum computers face a critical but overlooked challenge: classical control electronics must operate at 4 Kelvin to manage qubits effectively. This requirement creates engineering problems as complex as the quantum processors themselves, driving innovations in cryogenic semiconductor technology.