Nuclear Helicopter Will Hunt Life's Origins on Titan

TL;DR: Rotating detonation engines use continuous supersonic explosions to achieve 25% better fuel efficiency than conventional rockets. NASA, the Air Force, and private companies are now testing this breakthrough technology in flight, promising to dramatically reduce space launch costs and enable more ambitious missions.

The rocket engines that launched humanity to the Moon relied on controlled burning - a steady, predictable flame pushing spacecraft skyward. But what if we've been doing it wrong this whole time? What if the future of space travel lies not in carefully managing combustion, but in harnessing continuous explosions?

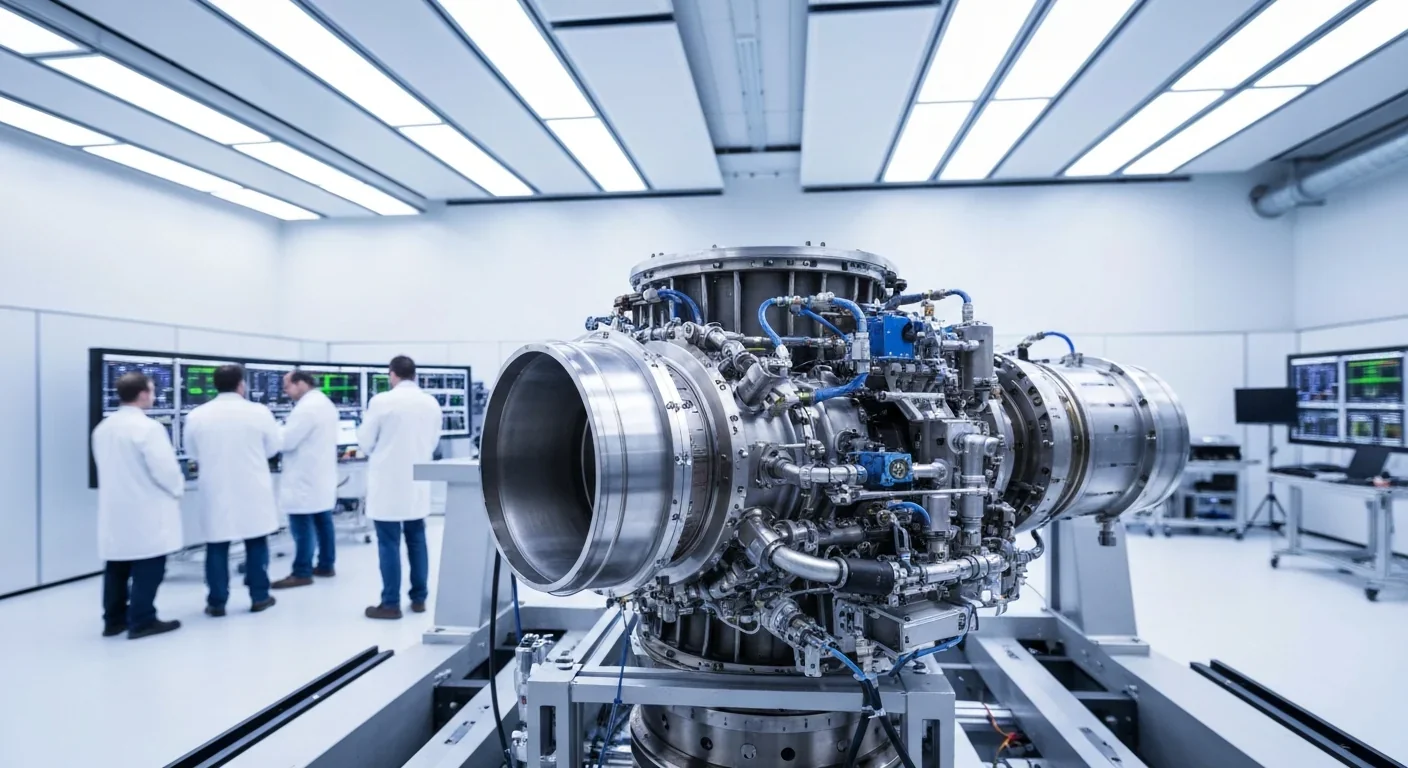

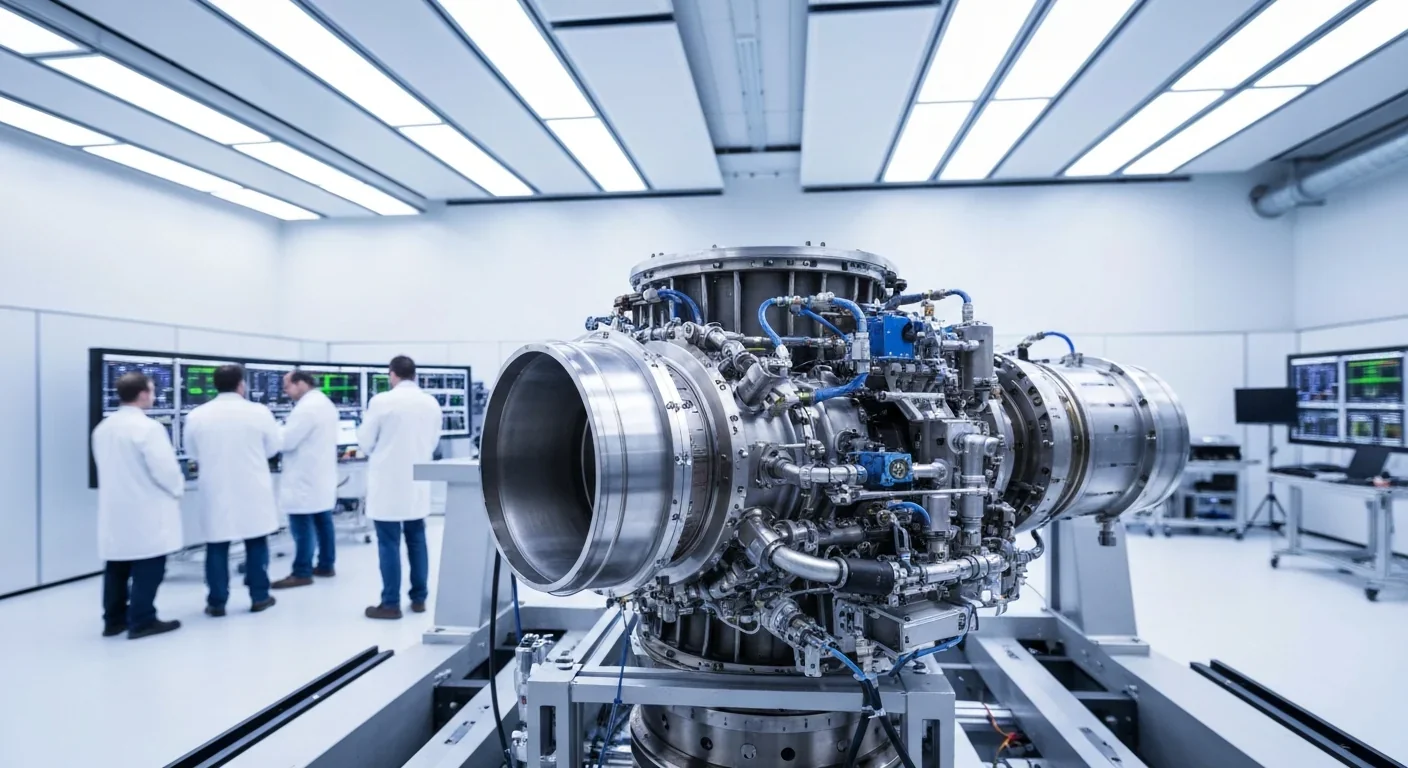

That's the radical promise of rotating detonation engines (RDEs), a technology that NASA, the U.S. Air Force, and private space companies are now racing to perfect. Unlike conventional rockets that burn fuel in a controlled deflagration, RDEs create supersonic detonation waves that circle the combustion chamber thousands of times per second. The result? Up to 25% greater fuel efficiency - a breakthrough that could fundamentally reshape what's possible in space exploration.

For decades, rotating detonation engines existed primarily as theoretical constructs and laboratory experiments. The physics seemed almost too good to be true: by maintaining a continuous detonation wave rather than using conventional burning, these engines could extract significantly more energy from the same amount of fuel.

The breakthrough came in 2024, when Venus Aerospace completed the first subsonic flight test of an RDE-powered aircraft at Spaceport America in New Mexico. Though the test lasted just one minute, it marked a pivotal moment - proof that these engines could actually work outside controlled laboratory conditions.

"This represents a new capability for physics-based understanding of rotating detonations."

- Aerospace America Research Summary

The company isn't alone in recognizing the potential. NASA's Marshall Space Flight Center partnered with Venus Aerospace to fire a 2-inch water-cooled RDE, gathering crucial scalability data for future hypersonic aircraft applications.

Meanwhile, Juno Propulsion won NASA's TechLeap Prize to fly the first rotating detonation engine in orbit - a demonstration that could validate the technology for actual spaceflight within the next few years.

To understand why RDEs matter, you need to grasp the difference between deflagration and detonation. Traditional rocket engines use deflagration: fuel burns at subsonic speeds, creating pressure that pushes the rocket forward. It's efficient enough, but it wastes a significant amount of energy.

Detonation is fundamentally different. In an RDE, fuel and oxidizer mix in an annular chamber - imagine a hollow cylinder. When ignited, a supersonic shockwave forms that travels around the chamber at speeds exceeding Mach 5. This detonation wave compresses the unburned fuel ahead of it, which then ignites, sustaining the wave in a continuous loop.

The detonation wave circles the combustion chamber thousands of times per second, creating pressure spikes that are far more efficient at converting chemical energy into thrust. This pressure gain combustion approach is what enables the 25% efficiency improvement over conventional engines.

Think of it like comparing a steady push to a rapid series of hammer blows. The hammering - the detonation - delivers more force from the same amount of energy input.

Making this work in practice has required solving problems that would have seemed insurmountable just a decade ago. The detonation waves generate extreme temperatures and pressures that can destroy engine components in seconds. Researchers have had to develop new materials, cooling systems, and manufacturing techniques to handle these brutal conditions.

RTX recently achieved positive thrust with their rotating detonation engine design, demonstrating that the technology can produce net propulsion despite the engineering challenges. The company's work focuses on integrating RDEs with existing turbine technology - a hybrid approach that could accelerate practical deployment.

One of the most significant advances came from researchers at the U.S. Air Force Research Laboratory, Argonne National Laboratory, and the University of Alabama in Huntsville. They developed ultra-high-speed imaging capable of capturing 5 million frames per second, allowing them to observe shock and detonation interactions at scales of 30 to 200 micrometers. This level of detail revealed "complicated breakup physics" that are now informing next-generation engine designs.

Purdue University and Argonne National Laboratory developed a hydrogen-air RDE with innovative nozzle guide vanes specifically for power generation - showing that the technology could have applications beyond propulsion, potentially revolutionizing how we generate electricity.

While American institutions lead much of the publicly disclosed research, this isn't solely a U.S. endeavor. China successfully tested what they claim is the world's first oblique detonation engine - a related technology that uses shockwaves from high-speed flight to trigger detonations.

The international competition adds urgency to the development timeline. Rotating detonation engines aren't just about cheaper satellite launches or more ambitious Mars missions. They're integral to hypersonic flight - aircraft that can travel at five times the speed of sound or faster.

Venus Aerospace is engineering a Mach 9 passenger jet that would use RDE technology to slash transpacific flight times from 12 hours to under two hours. The company has already attracted backing from Lockheed Martin, validating both the technical approach and the market potential.

The military applications are equally significant. The U.S. Air Force has been testing rotating detonation engines for high-performance missiles, where the combination of efficiency and power density could enable weapons with unprecedented range and speed.

The U.S. Air Force has been testing rotating detonation engines for high-performance missiles, where the combination of efficiency and power density could enable weapons with unprecedented range and speed.

The path from laboratory success to operational engines follows a carefully staged progression. Current efforts span multiple parallel tracks, each addressing different aspects of the technology:

Materials Science: Researchers at Meyer Research Group are developing new solid fuels specifically optimized for RDEs, expanding the range of propellants beyond traditional liquid fuels.

Computational Modeling: Teams are using large-eddy simulations and computational fluid dynamics to understand the complex flow dynamics inside rotating detonation combustors. These models help predict performance without requiring expensive physical tests.

Integration Engineering: Companies like GT-SUITE are developing simulation tools that allow engineers to model how RDEs will perform when integrated into complete propulsion systems.

Diagnostic Technology: Advanced laser diagnostic techniques, including megahertz-rate planar laser-induced fluorescence, are providing unprecedented visibility into the combustion processes, generating benchmark data that validates theoretical models.

One ambitious near-term milestone: plans to retrofit a Rolls-Royce M250 engine with a hydrogen-powered RDE. This would demonstrate that the technology can work with modified versions of existing engines, potentially accelerating adoption.

Twenty-five percent greater fuel efficiency translates directly to massive cost savings. SpaceX has already revolutionized space access by reducing launch costs through reusability. RDEs promise a complementary revolution through improved engine performance.

Consider a typical satellite launch that consumes hundreds of tons of propellant. A 25% efficiency gain means either carrying less fuel (reducing launch vehicle size and cost) or achieving greater payload capacity (launching more satellites per mission). For Mars missions requiring years of travel, the fuel savings become even more dramatic.

The implications extend beyond pure cost savings. More efficient engines enable missions that are currently impossible. Deep space probes could carry more scientific instruments. Crewed missions to Mars could launch with larger habitats and more supplies. Satellite constellations could reach orbit at a fraction of current costs.

Research published in academic journals confirms the theoretical advantages while documenting the engineering challenges that remain. The consensus among aerospace researchers is clear: the thermodynamic benefits are real, but translating those benefits into reliable, flight-ready hardware requires overcoming significant technical hurdles.

Unlike previous aerospace technologies that developed along separate military and commercial tracks, RDEs are advancing on both fronts simultaneously. The same engine that could power a hypersonic passenger jet could also propel next-generation missiles.

The U.S. Navy began exploring rotating detonation engines more than a decade ago, recognizing their potential for naval propulsion and weapons systems. Recent tests by the Air Force Research Laboratory and DARPA have focused on integrating RDEs with various missile platforms.

This dual-use nature accelerates development by drawing funding from both defense budgets and commercial investment. Venus Aerospace's partnership with both NASA and Lockheed Martin exemplifies this convergence, allowing the Houston-based company to advance hypersonic passenger flight while also supporting military applications.

"The question isn't whether RDEs will be developed - the technology is too promising to abandon. The question is which nation will master the technology first and how quickly it will transition from experimental test stands to operational systems."

- Aerospace Industry Analysis

Despite the promising test results, significant obstacles remain before RDEs become commonplace. The extreme operating conditions create materials challenges that current engineering solutions barely address. Detonation waves generate thermal stresses that can crack or melt combustion chamber walls within minutes of operation.

Controlling the detonation wave itself presents another challenge. In some operating conditions, multiple detonation waves can form, creating unpredictable thrust variations. Researchers are developing active control systems that can stabilize the combustion process, but reliable control across all flight regimes remains elusive.

Integration with existing aerospace systems adds complexity. RDEs produce highly unsteady exhaust flows - the pressure oscillates dramatically as detonation waves pass. These pressure variations can damage downstream components like turbines or nozzles. Engineers must design entirely new integration architectures that can handle this turbulent output.

Research teams are using uncertainty quantification methods to understand how variations in manufacturing, fuel quality, and operating conditions affect engine performance. This probabilistic approach helps identify the most critical parameters that must be controlled for reliable operation.

Then there's the fuel question. Most RDE research uses hydrogen, which offers excellent detonation characteristics but requires complex storage and handling infrastructure. Developing engines that work efficiently with kerosene, methane, or other practical aerospace fuels remains an active research area.

The development timeline for RDEs is becoming clearer as key milestones approach. NASA's ongoing research program aims to characterize RDE performance across a range of scales and operating conditions, building the knowledge base needed for flight certification.

Juno Propulsion's planned orbital demonstration could happen as early as 2025, providing the first data on how RDEs perform in the space environment. Success would validate the technology for satellite station-keeping and orbit-raising maneuvers - applications where even modest efficiency gains translate to extended mission lifespans.

Venus Aerospace plans progressive flight tests of their hypersonic aircraft engine demonstrator, gradually pushing toward the Mach 9 speeds their passenger jet concept requires. Each test builds confidence while revealing new challenges that must be solved.

Meanwhile, defense applications may reach operational status first. The military's tolerance for higher costs and its need for performance advantages create a pathway for RDE technology to mature before commercial adoption. A hypersonic missile using an RDE could be operational within five years, even if hypersonic passenger aircraft remain a decade away.

The timeline depends heavily on solving the materials and control challenges. Breakthroughs in high-temperature ceramics, additive manufacturing, or active combustion control could accelerate development dramatically. Conversely, if thermal management proves more difficult than anticipated, timelines could stretch.

RDEs represent more than just a better rocket engine - they're part of a broader transformation in how humanity accesses and uses space. Combined with reusable launch vehicles, in-space manufacturing, and advanced materials, highly efficient propulsion could make space truly affordable.

Consider the downstream effects of cutting launch costs by another 25%. Suddenly, space-based solar power becomes economically viable. Building large space stations or lunar bases becomes affordable. Scientific missions to the outer planets can carry more instruments and achieve faster transit times.

The technology could also enable single-stage-to-orbit vehicles - spacecraft that reach orbit without dropping stages. This holy grail of aerospace engineering has remained frustratingly out of reach, largely because rocket engines weren't quite efficient enough. RDEs might finally tip the balance.

For pressure gain combustion technologies more broadly, rotating detonation engines represent the most promising near-term application. Success with RDEs could accelerate development of related concepts like pulse detonation engines or oblique detonation engines, each with their own advantages for specific applications.

The transition from controlled burning to controlled detonation marks a fundamental shift in propulsion philosophy. For more than a century, engineers sought to prevent detonation, viewing it as a destructive failure mode. RDEs flip that paradigm, harnessing detonation as the primary combustion mechanism.

This mental shift parallels other technological revolutions where what was once considered a bug became a feature. Early computer engineers viewed electricity leakage as a problem to minimize; modern processors deliberately harness quantum tunneling effects. Aerodynamicists once feared the shock waves that form at transonic speeds; supersonic aircraft now use those shocks to generate lift.

The research community has embraced this new paradigm. Academic papers on RDEs have grown from occasional theoretical studies to hundreds of detailed investigations examining every aspect of performance, from combustion dynamics to thermal management to acoustic signatures.

Aerospace America's coverage of RDE advances documents how the technology has moved from the fringes to the mainstream of propulsion research. Professional societies now host dedicated sessions on rotating detonation engines, and major aerospace companies have established internal research programs.

The next chapter in space exploration won't be written with the same engines that took us to the Moon. It will be written with new technologies that seem almost impossibly ambitious - until suddenly they're not.

Rotating detonation engines fit that pattern perfectly. A decade ago, most aerospace engineers viewed them as fascinating physics experiments with little practical application. Today, they're flying on test aircraft, being integrated into missile systems, and scheduled for orbital demonstrations.

The 25% efficiency gain isn't the ceiling - it's the floor. As engineers better understand detonation physics, optimize chamber geometries, and develop purpose-built materials, performance will improve further. Some projections suggest efficiency gains could eventually reach 30% or even 35% compared to conventional engines.

What makes this revolution particularly significant is its timing. As humanity stands on the cusp of becoming a truly spacefaring civilization - with lunar bases, Mars missions, and asteroid mining transitioning from science fiction to engineering projects - we're simultaneously developing the propulsion technology to make those ambitions affordable.

The rocket engine that explodes on purpose might sound like a paradox. But it's becoming clear that controlled detonation represents the future of propulsion. The engines launching spacecraft in 2035 will look very different from those flying today. They'll be more efficient, more powerful, and - ironically - built around technology that earlier generations of engineers spent their careers trying to prevent.

We're not just improving rocket engines. We're fundamentally rethinking how to convert chemical energy into motion, opening pathways to space that were previously closed by the economics of conventional propulsion. The future of space travel is being forged today, one supersonic detonation wave at a time.

Rotating detonation engines use continuous supersonic explosions to achieve 25% better fuel efficiency than conventional rockets. NASA, the Air Force, and private companies are now testing this breakthrough technology in flight, promising to dramatically reduce space launch costs and enable more ambitious missions.

Triclosan, found in many antibacterial products, is reactivated by gut bacteria and triggers inflammation, contributes to antibiotic resistance, and disrupts hormonal systems - but plain soap and water work just as effectively without the harm.

AI-powered cameras and LED systems are revolutionizing sea turtle conservation by enabling fishing nets to detect and release endangered species in real-time, achieving up to 90% bycatch reduction while maintaining profitable shrimp operations through technology that balances environmental protection with economic viability.

The pratfall effect shows that highly competent people become more likable after making small mistakes, but only if they've already proven their capability. Understanding when vulnerability helps versus hurts can transform how we connect with others.

Leafcutter ants have practiced sustainable agriculture for 50 million years, cultivating fungus crops through specialized worker castes, sophisticated waste management, and mutualistic relationships that offer lessons for human farming systems facing climate challenges.

Gig economy platforms systematically manipulate wage calculations through algorithmic time rounding, silently transferring billions from workers to corporations. While outdated labor laws permit this, European regulations and worker-led audits offer hope for transparency and fair compensation.

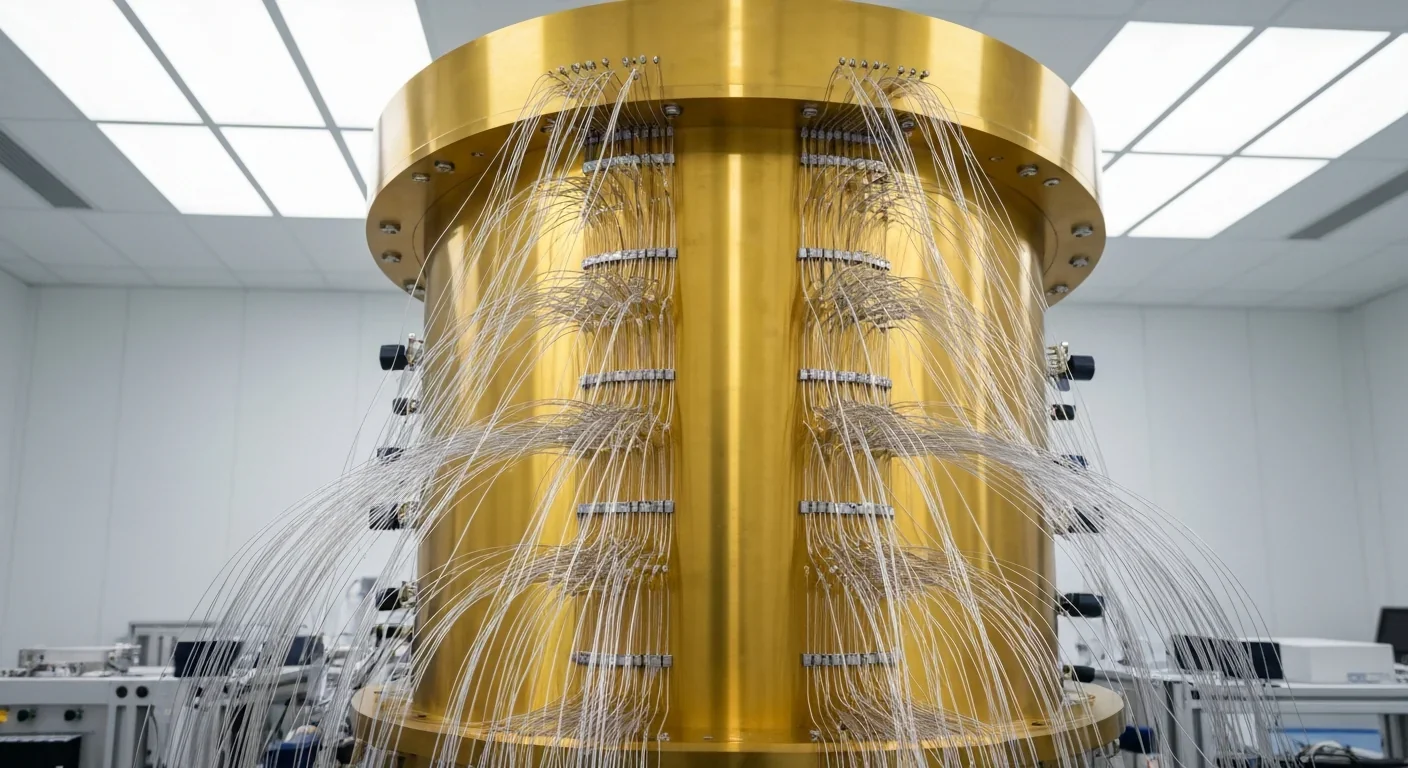

Quantum computers face a critical but overlooked challenge: classical control electronics must operate at 4 Kelvin to manage qubits effectively. This requirement creates engineering problems as complex as the quantum processors themselves, driving innovations in cryogenic semiconductor technology.