Ice Volcano on Ceres Hints at Hidden Ocean

TL;DR: Space elevator technology remains decades away despite recent material breakthroughs. HydroGraph's fractal graphene synthesis shows promise, but manufacturing defect-free cables at 100,000-kilometer scale remains unsolved.

Picture this: a cable stretching 100,000 kilometers from Earth's surface into space, strong enough to lift entire payloads without a single rocket. It sounds like pure science fiction, something Arthur C. Clarke dreamed up in 1979. But here's the twist - engineers are now arguing that the materials and physics to make it happen might already exist. The question isn't whether a space elevator is possible anymore. It's whether we're ready to build it.

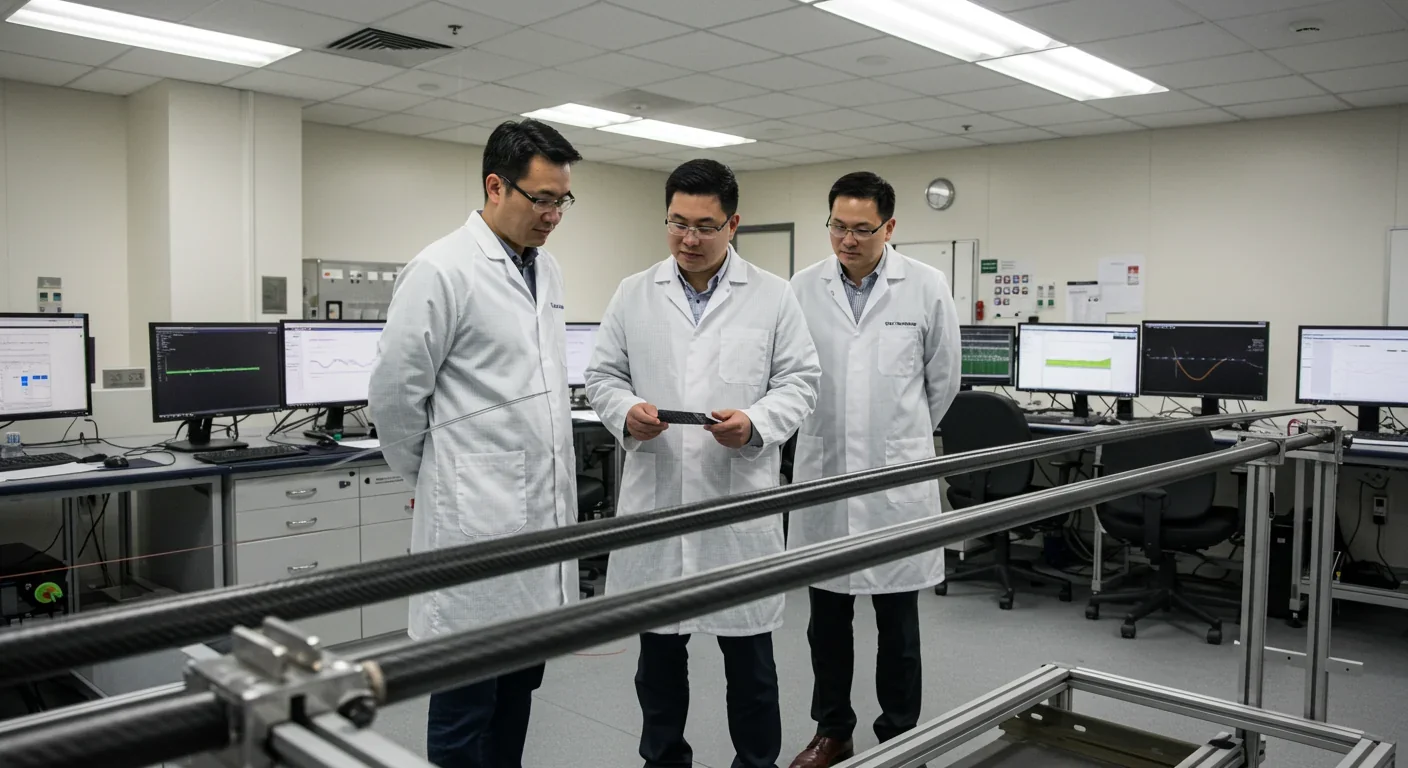

In September 2025, researchers announced something extraordinary. HydroGraph Clean Power unveiled a detonation synthesis process that creates graphene with over 99.8% purity, featuring a fractal, snowflake-like structure with 200 square meters of surface area per gram. This isn't just another laboratory curiosity - it's a potential game-changer for space elevator tethers.

Why does this matter? Graphene's theoretical tensile strength hits 130 gigapascals, with a density of just 2.2 grams per cubic centimeter. That yields a specific strength around 59 GPa·cm³/g, right at the threshold needed for a space elevator. Traditional materials like steel or Kevlar don't even come close. The fractal morphology allows these platelets to interlock like puzzle pieces, creating far superior load transfer at low filling fractions.

But here's where reality bites. Carbon nanotubes have been the poster child for space elevator materials for decades, yet we still can't manufacture them at the required scale. As Alexander Wallace Watson, who formerly worked with LiftPort, bluntly stated: "The main bottleneck is material. The stuff needed to build it does not yet exist in bulk."

The space elevator concept has been around longer than most people realize. Russian scientist Konstantin Tsiolkovsky first proposed the idea in 1895, inspired by the Eiffel Tower. But it remained firmly in the realm of fantasy until materials science began catching up with imagination in the late 20th century.

Arthur C. Clarke's 1979 novel The Fountains of Paradise popularized the concept, depicting a tether connecting Earth to geostationary orbit. Clarke himself acknowledged the primary obstacle: we simply didn't have materials strong enough. For decades, that remained true. Steel cables would snap under their own weight long before reaching orbital heights. Kevlar, while stronger, still fell short by orders of magnitude.

The discovery of carbon nanotubes in 1991 changed everything. Here, finally, was a material with the theoretical strength-to-weight ratio needed. Suddenly, what seemed impossible became merely extraordinarily difficult. Scientists began calculating optimal tether designs, climber mechanisms, and deployment strategies. Organizations like the International Space Elevator Consortium formed to coordinate research. In 2012, Obayashi Corporation, a major Japanese construction firm, announced plans to build a space elevator by 2050.

Yet progress has been frustratingly slow. Manufacturing even small quantities of defect-free carbon nanotubes remains prohibitively expensive and technically challenging. Creating continuous fibers kilometers long - let alone the 100,000 kilometers needed for a full tether - has proven elusive.

Let's talk about what it actually takes to build a space elevator. You need a tether anchored at Earth's equator, extending past geostationary orbit at 36,000 kilometers, with a counterweight positioned even farther out to maintain tension against Earth's gravity. The entire structure must be strong enough to support not just its own enormous weight but also climbers carrying payloads up and down.

The orbital dynamics are brutally unforgiving. The tether needs to stay perfectly aligned with Earth's rotation, extending from the equator straight up through the atmosphere, past low Earth orbit, through the Van Allen radiation belts, and out to geostationary orbit and beyond. Any deviation creates catastrophic stress concentrations.

Then there's the environment. Space isn't empty - it's filled with hazards. Micrometeoroids zip through at velocities that could shred conventional materials. Atomic oxygen in low Earth orbit corrodes surfaces. Radiation degrades molecular bonds over time. Atmospheric drag, lightning strikes, and electromagnetic interference all pose threats.

We got a glimpse of these challenges from an unexpected source. In 2035, inspectors examining a space elevator cable that had been operational since 2028 discovered irregularities in tensile strength and surface integrity. The high-tensile carbon nanotube composite showed microfractures and material fatigue exceeding expected thresholds after just seven years.

Dr. Elena Martinez, lead engineer for Orbital Technologies Inc., stated: "While we anticipated some wear and tear due to the harsh conditions of space, the extent of these anomalies is concerning." This real-world data suggests that even with breakthrough materials, long-term integrity requires robust maintenance protocols.

Creating the tether is perhaps the most daunting challenge. Current proposals suggest using wet-spinning to create fibers from high-solid graphene dispersions, then braiding and using hot-isostatic pressing to forge inter-platelet bonds. Some researchers are exploring bio-templating with engineered proteins that mimic spider silk's hierarchical structure, potentially creating composites with near-single-crystal strength.

But transitioning from nanoscale materials to a macroscale cable spanning tens of thousands of kilometers introduces countless failure points. Each connection, each interface between sections, represents a potential weak link. Maintaining consistent quality across that length is unprecedented in human engineering.

Deployment poses its own puzzles. Do you build from orbit downward, extending the tether while simultaneously deploying the counterweight upward? Or do you launch sections from Earth and assemble in space? Either approach requires precision that makes launching the James Webb Space Telescope look straightforward.

Here's where things get interesting. Rocket launches are expensive - SpaceX's Falcon 9 costs around $62 million per launch as of 2020, though reusability cuts about $15 million off that figure. Even Starship's projected fully-reusable cost of $2-10 million per launch is orders of magnitude higher than what a space elevator could theoretically achieve.

Once operational, a space elevator could transport payload to orbit for a fraction of rocket costs - potentially as low as $100-500 per kilogram versus thousands of dollars per kilogram on current systems. The structure becomes a reusable piece of infrastructure rather than a consumable launch vehicle.

But there's a catch: construction costs. While specific estimates vary wildly and remain speculative, building a space elevator would require an investment measured in tens of billions of dollars, possibly approaching $100 billion. The return on that investment depends on throughput and operational lifespan - both of which remain highly uncertain.

The seven-year service life observed before significant degradation suggests that maintenance and replacement cycles could substantially increase operational costs. Factor in inspection protocols, repair missions, and potential catastrophic failure modes, and the economic case becomes more complex.

While Earth-based space elevators face formidable material constraints, there's an intriguing alternative: a lunar elevator. The Moon's lower gravity fundamentally changes the engineering requirements. Alexander Wallace Watson points out that a lunar tether "could be built with what exists today, though it would still require solving serious engineering problems."

A lunar elevator would connect the Moon's surface to the Earth-Moon L1 Lagrange point, roughly 56,000 kilometers away. The reduced gravity means existing high-strength materials could work. But there's a geopolitical twist: "Because of orbital dynamics, there can be only one Lunar Elevator." Whoever builds it first controls a monopoly on efficient lunar resource extraction.

This strategic reality could accelerate development. The lunar elevator offers a more achievable near-term goal that could validate technologies and operating procedures before attempting an Earth-based system.

Let's be blunt: a fully operational Earth-based space elevator by 2025 isn't happening. The timeline is unrealistic given our current technology readiness levels. We can't yet manufacture defect-free carbon nanotube or graphene cables at the required scale. Deployment mechanisms remain untested. Environmental durability questions persist.

But that doesn't mean progress has stalled. The International Space Elevator Consortium continues hosting conferences focused on "Strong Materials for the Space Elevator: Status and Behavior at the Climber-Tether Interface." Researchers are making genuine advances in material science, composite engineering, and fabrication techniques.

A more realistic timeline puts us decades away from an operational system. Obayashi Corporation's 2050 target date may still be optimistic, but it's at least plausible. The path forward likely involves incremental steps: developing longer continuous nanotube fibers, testing prototype tethers in space, potentially building a lunar elevator first as proof-of-concept.

The space elevator represents something profound: infrastructure that fundamentally transforms our relationship with space. Right now, every launch is an event - expensive, risky, and resource-intensive. A space elevator turns space access into something more like taking an elevator to another floor. Routine. Affordable. Open to a far wider range of payloads and missions.

That transformation could enable space-based solar power, large-scale orbital manufacturing, easier access to asteroid resources, and genuine space colonization. The economic implications ripple through industries from communications to materials science to tourism.

But we need to be honest about where we are. Material science breakthroughs like HydroGraph's fractal graphene synthesis are genuinely exciting, yet they're still far from being production-ready for a 100,000-kilometer tether. The operational reality of even a functioning space elevator shows that advanced materials alone aren't sufficient - systemic maintenance and environmental shielding are essential.

The dream of a space elevator has evolved from pure science fiction to serious engineering research. We've identified the physics, mapped out the requirements, and even found materials that theoretically work. What remains is the hardest part: turning theory into reality, scaling laboratory achievements to infrastructure-scale deployment, and solving the thousands of engineering challenges that emerge when attempting something unprecedented.

Engineers today aren't asking whether a space elevator is possible. They're working through how to actually build one. That's progress worth celebrating, even if it means acknowledging that 2025 was never a realistic target. The space elevator is coming - just not quite as soon as the headlines might suggest.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

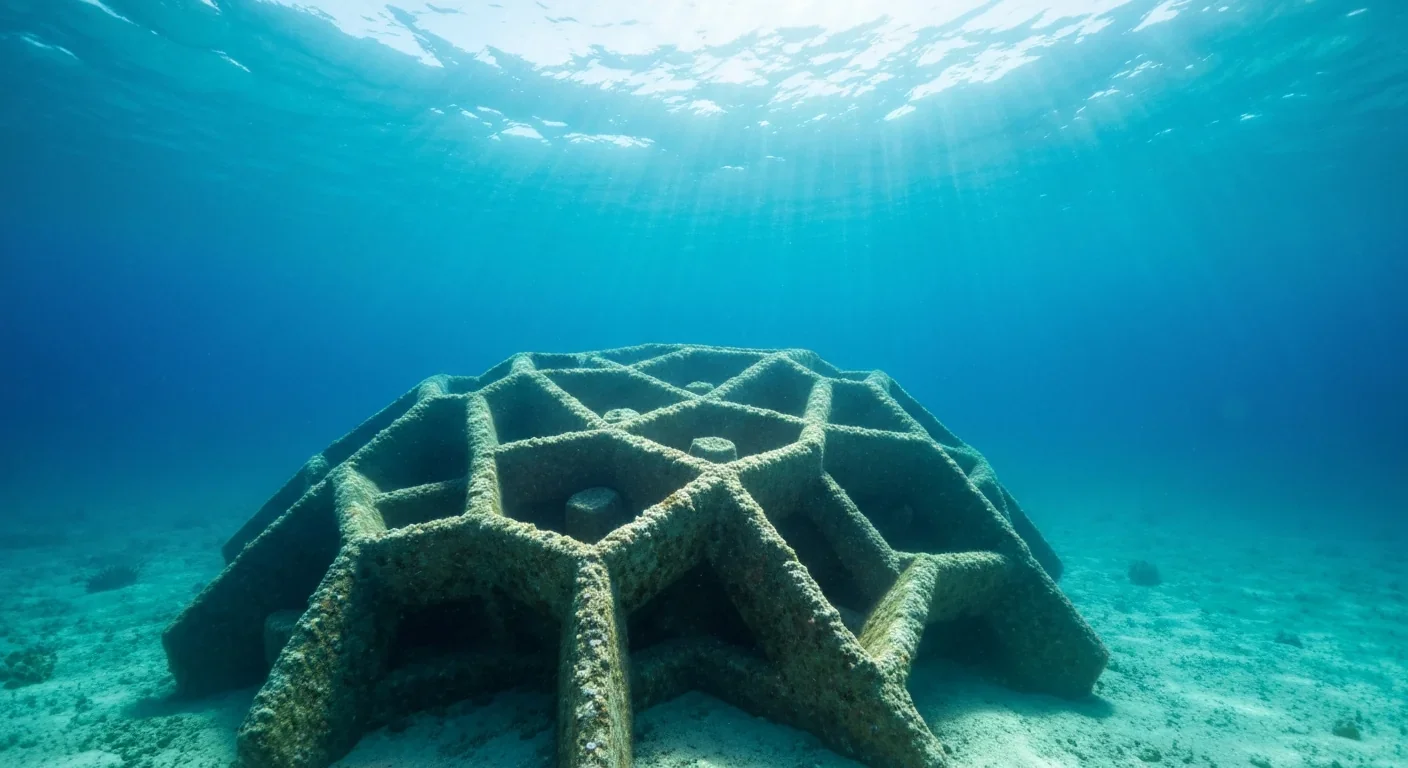

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

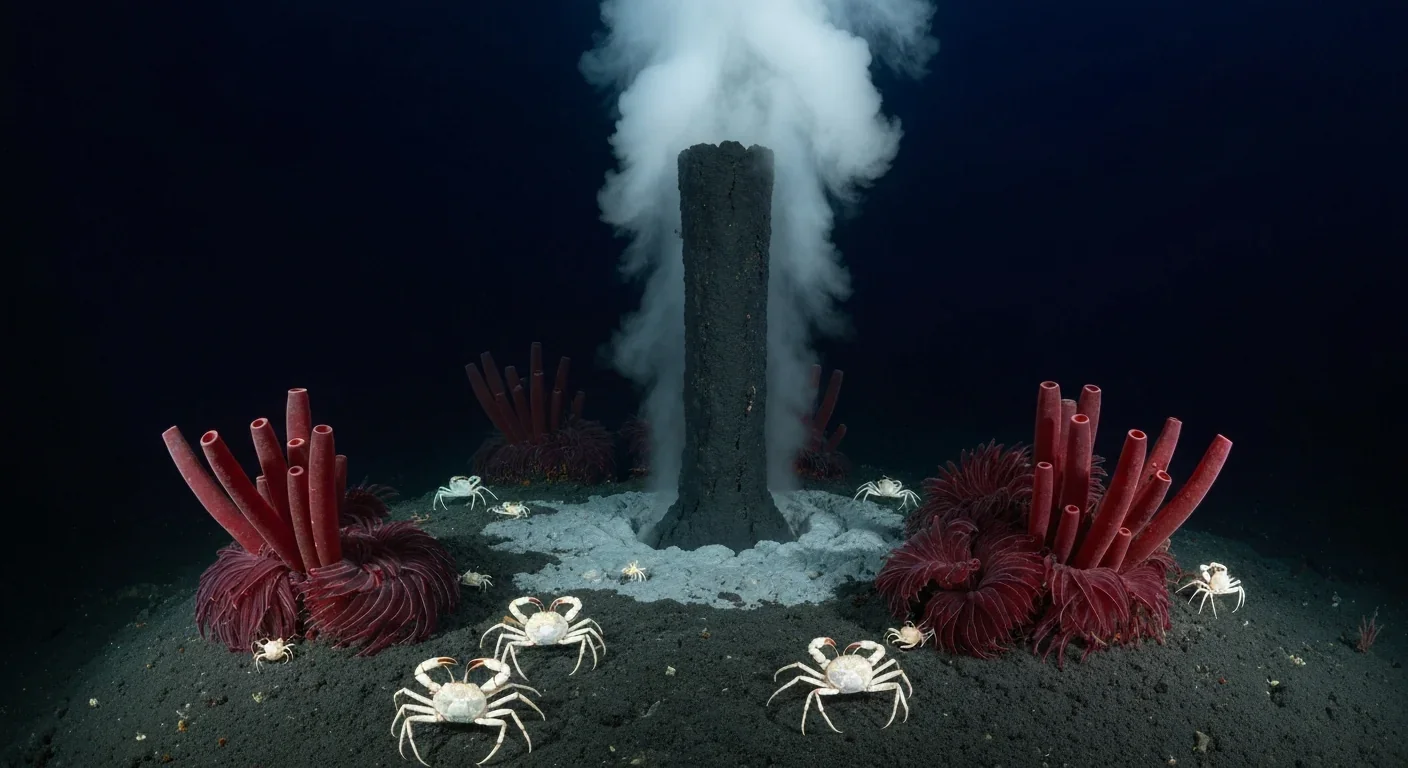

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

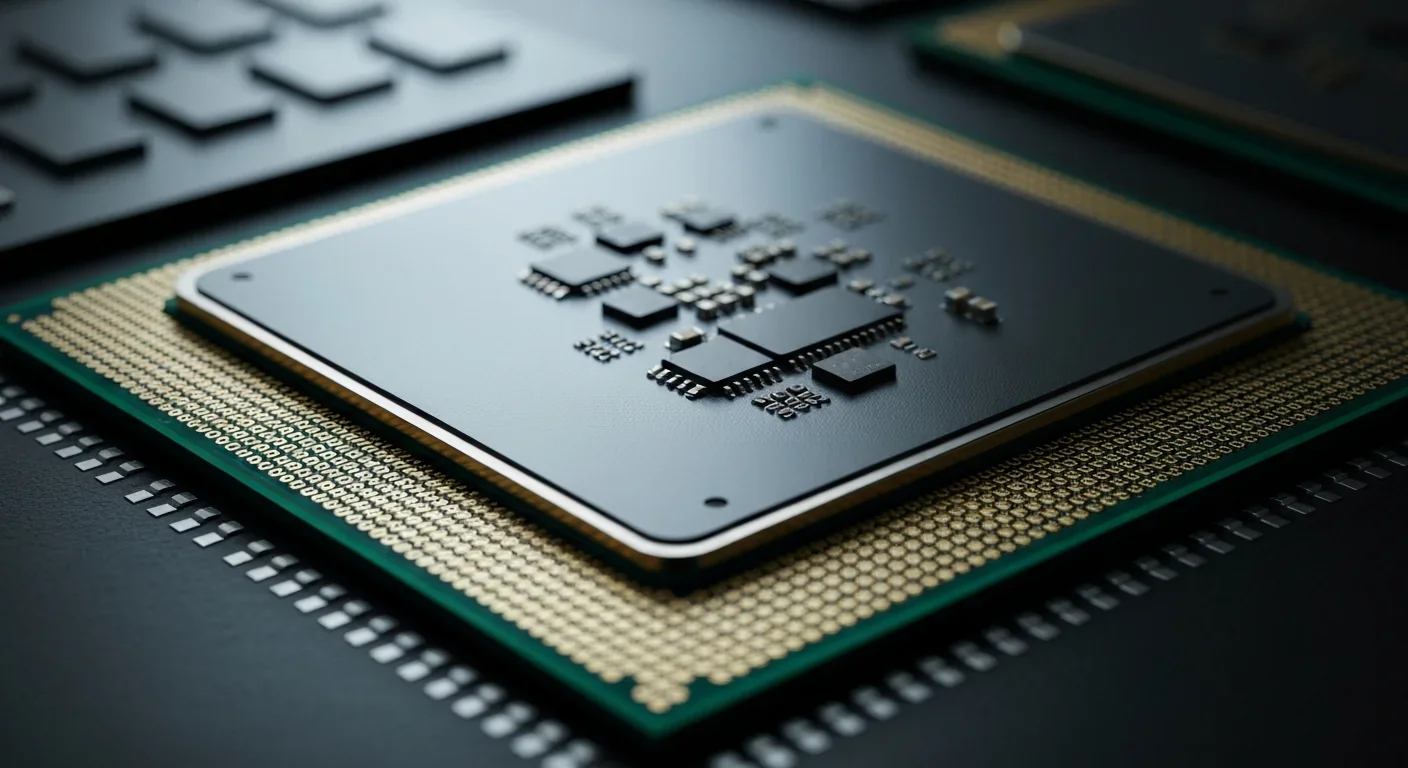

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.