Ice Volcano on Ceres Hints at Hidden Ocean

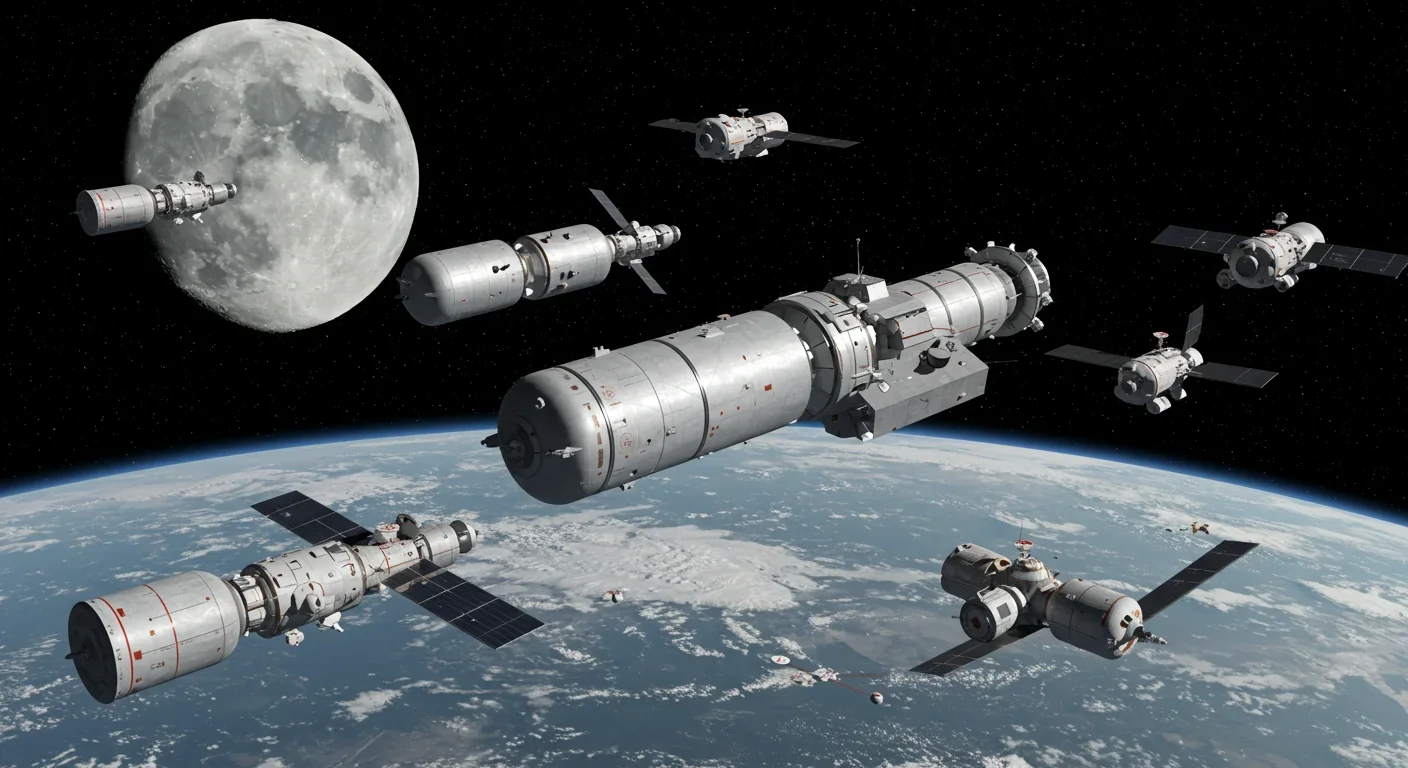

TL;DR: Orbital refueling depots will transform space exploration by enabling spacecraft to refuel in orbit rather than carrying all fuel from Earth, making Mars missions and deep space travel economically viable for the first time.

By 2030, a revolutionary infrastructure will orbit Earth, fundamentally transforming how humanity explores space. These aren't satellites or space stations in the traditional sense. They're fuel depots, orbital gas stations that will make Mars missions economically viable and turn one-way deep space trips into reusable journeys. Without them, the next generation of lunar bases, asteroid mining operations, and crewed Mars missions simply can't happen.

The concept sounds straightforward. Launch a rocket, dock with a fuel depot in orbit, fill up, then head to your destination. But the reality involves solving engineering challenges that would make any terrestrial gas station owner's head spin. Transferring cryogenic propellants at temperatures hundreds of degrees below zero, in an environment where liquids don't settle and boiling behaves completely differently than on Earth, requires technologies that are only now becoming possible.

Every kilogram matters when you're launching from Earth. The tyranny of the rocket equation means that carrying fuel for a round trip to Mars requires enormous amounts of propellant, which itself requires more fuel to lift, creating a vicious cycle. Current launch costs make this approach prohibitively expensive for anything beyond the Moon.

In-space refueling changes the equation entirely. Launch your spacecraft with just enough fuel to reach low Earth orbit. Refuel there from a depot that was filled by cheaper, dedicated tanker flights. Suddenly, missions that seemed economically impossible become feasible. As Gary Henry from the Defense Innovation Unit puts it, "You can refuel on orbit in LEO and add nine kilometres per second to your vehicle. You pretty much unlock the solar system at that point in time."

The economic transformation goes beyond just fuel costs. Reusability becomes practical for deep space missions. A spacecraft can make multiple trips between Earth orbit and the Moon, or serve as a reusable Mars shuttle, dramatically reducing the per-mission cost. Instead of building and launching a new spacecraft for every mission, we build infrastructure once and use it repeatedly.

NASA's Artemis program depends entirely on this technology. The agency's plan to return humans to the Moon requires SpaceX's Starship Human Landing System to refuel in orbit before heading to the lunar surface. Without that orbital refueling capability, the mission can't happen. We're not talking about a nice-to-have technology anymore. It's mission-critical.

The technical challenges start with a fundamental problem: liquids don't settle in microgravity. On Earth, gravity pulls fuel to the bottom of a tank. Open the valve, and fuel flows predictably. In orbit, surface tension dominates. Fuel clings to tank walls, forms floating blobs, and refuses to behave.

Research at the University of Florida reveals just how different space is. "Boil-off behavior in space is completely different from on Earth because there's no buoyancy in microgravity," explains Jacob Chung, who leads a team testing thin-film coatings designed to suppress boiling in reduced gravity. Traditional insulation adds mass that rockets can't afford. These new coatings are extremely lightweight and actively reduce boil-off, offering a promising alternative.

Then there's the temperature problem. We're not talking about gasoline here. The most efficient rocket propellants are cryogenic: liquid oxygen at -183°C and liquid methane at -162°C. These temperatures create engineering nightmares. Even tiny heat leaks cause propellant to boil away. NASA's Zero Boil-Off Tank research investigates how noncondensable gases interfere with fuel storage systems in microgravity, a problem that doesn't exist in Earth-based tanks.

The European Union's CRYSALIS project tackles these challenges head-on. This collaborative effort is developing systems for the transfer and long-term storage of cryogenic propellant in microgravity, culminating in a six-month small-scale orbital demonstration. They're using acoustic measurement techniques to provide precise propellant quantity management in space, a solution that sounds simple but required years of development.

Docking adds another layer of complexity. Two massive spacecraft, each carrying thousands of kilograms of explosive fuel, must connect precisely in orbit. The docking ports and quick-disconnect systems being integrated into SpaceX's Starship Block 3 variants represent a decisive engineering step. These aren't the gentle, slow docking procedures used for crew transfers. They need to handle high flow rates to transfer propellant quickly, before too much boils off.

SpaceX leads the pack with its Starship refueling architecture. Elon Musk estimates that eight launches would be needed to completely refuel a Starship in low Earth orbit. NASA's calculations are even more conservative, estimating 16 launches in short succession would be needed to partially refuel Starship for one lunar landing. Those numbers sound daunting, but they're economically viable if you're reusing the tankers and the spacecraft being refueled.

The company isn't developing this technology in isolation. The Defense Innovation Unit is collaborating with SpaceX to test an in-space refueling architecture for Starship, indicating that military and civil space operations will both depend on this capability. The partnership aims to create standards that would be leverageable by the broader community, not just SpaceX.

NASA's approach extends beyond SpaceX. The Lunar Gateway will serve as a staging point in lunar orbit, with its Power and Propulsion Element designed to be refuelable. This small space station will enable reusable lunar landers to operate between Gateway and the Moon's surface, dramatically reducing the cost per mission.

Traditional aerospace contractors are also entering the market. Northrop Grumman received two contracts from the U.S. Space Force for in-space refueling services. Their SpaceLogistics division is developing satellite servicing capabilities that include refueling, demonstrating that this technology has applications beyond deep space exploration.

The international community isn't sitting idle. France's CNES space agency issued a call for in-orbit refueling services demonstration, joining the European Union's CRYSALIS effort. These aren't just research projects. They're building operational capabilities with near-term deployment timelines.

The technology is advancing faster than most people realize. SpaceX plans to demonstrate orbital refueling as early as 2026, a necessary milestone before Artemis III's currently scheduled 2027 lunar landing. That's an aggressive timeline, but SpaceX has a track record of achieving what others thought impossible.

NASA's Cryogenic Fluid Management technology program is running parallel efforts. They're developing everything from advanced insulation to propellant transfer systems, with components being tested on suborbital flights and the International Space Station. A mass gaging system developed with NASA funding will measure fuel transfer in zero gravity, solving the "how much fuel do I have" problem that's trivial on Earth but complex in space.

The CRYSALIS six-month orbital demonstration represents another critical milestone. Unlike quick proof-of-concept tests, this extended mission will validate that cryogenic propellants can be stored and transferred reliably over the timeframes required for actual missions. Long-duration storage is essential because Mars missions might require spacecraft to sit fueled in orbit for weeks or months, waiting for optimal launch windows.

Commercial startups are also pushing the technology forward. Orbit Fab positions itself as creating "gas stations in space" for the satellite servicing market, starting with non-cryogenic propellants but building infrastructure and expertise that will scale to larger depots. Their approach focuses on establishing the business model and operational procedures while the technology matures.

Blue Origin's Blue Moon lunar lander incorporates refueling capability in its design, though the company has been less vocal about specific timelines than SpaceX. Multiple competing architectures reaching development simultaneously suggests that the technology is maturing beyond the research phase into operational deployment.

The implications extend far beyond making existing missions cheaper. In-space refueling enables entirely new mission architectures that were previously impossible.

Reusable lunar shuttles become practical. A spacecraft stationed in lunar orbit can ferry cargo and crew between Gateway and the surface repeatedly. Each mission costs only the propellant and maintenance, not an entire new spacecraft. This approach mimics how aviation transformed from one-time flights to scheduled airline service.

Mars missions shift from "all or nothing" ventures to incremental campaigns. Send cargo ahead on slower, more efficient trajectories. Humans follow on faster routes, knowing their supplies are already waiting. If something goes wrong, they're not committed to a two-year round trip in a potentially crippled spacecraft. The ability to refuel in orbit means abort options exist that don't with current architectures.

Asteroid mining transitions from science fiction to economically plausible. The challenge with asteroids isn't reaching them, it's bringing valuable materials back. A mining spacecraft that can refuel in Earth orbit, visit an asteroid, and return to orbit for refueling again suddenly makes economic sense. The high upfront cost is amortized across multiple missions.

Scientific missions gain flexibility they've never had. Missions to the outer planets currently require precise launch windows and gravitational assists, sometimes waiting years for optimal conditions. With refueling capability, spacecraft can take more direct routes or change targets mid-mission. A probe that discovers something interesting on one of Jupiter's moons could refuel and investigate further instead of flying past once and being done.

The Lunar Gateway's role exemplifies this new flexibility. Rather than being a destination itself, it becomes a node in a transportation network. Spacecraft refuel there before heading to the lunar surface, Mars, or deeper into the solar system. It's the difference between having one airport versus having a global network.

The economics work because of reusability and scale. Launch costs have dropped dramatically over the past decade, from $65,000 per kilogram on the Space Shuttle to around $1,500 per kilogram on SpaceX's Falcon 9. Starship aims to push that below $100 per kilogram through full reusability. At those prices, dedicating multiple launches to filling an orbital depot becomes economically rational.

Consider the alternative. A Mars mission might require 1,000 tons of propellant. Launching that all at once, or trying to carry it from Earth's surface in a single vehicle, pushes against physics and economics. But spread across 15-20 tanker flights of a reusable rocket? The math starts working.

The business model extends beyond government missions. Commercial satellite operators want to extend spacecraft lifetimes through refueling. Space tourism ventures need reusable shuttles that can make multiple trips. Manufacturing in space will require cargo transport that doesn't cost millions per flight. All these applications create a market for depot services.

French space agency interest in cryogenic in-orbit refueling technologies signals that this will become a competitive international market, not a U.S. monopoly. Multiple providers means competitive pressure, driving costs down and reliability up. The space economy expands when infrastructure exists to support it.

The parallel to terrestrial infrastructure is striking. Railroads enabled the industrial revolution not because trains were amazing (though they were), but because the infrastructure of tracks, stations, and scheduled service made commerce predictable and affordable. Orbital refueling depots could play a similar catalytic role for the space economy.

Technical risks remain significant. No one has transferred large quantities of cryogenic propellant between spacecraft in orbit. The physics is understood, the components are being developed, but system-level demonstration still lies ahead. A failed transfer during a critical mission could strand astronauts or doom expensive spacecraft.

Safety protocols for cryogenic propellant transfer need development. These aren't small risks. A leak during docking could create a combustible mixture. Thermal stress from rapid temperature changes could crack tanks. Collision during docking could be catastrophic. Each risk requires mitigation strategies, backup systems, and extensive testing.

The logistical complexity is daunting. SpaceX's plan requiring 8-16 launches to fuel a single mission means multiple launches must succeed in quick succession. Each delay compounds. A grounded tanker fleet means missions can't proceed. This level of operational tempo has no precedent in spaceflight.

Political and funding uncertainties cloud timelines. Artemis has already experienced delays and budget pressures. If refueling technology proves more difficult or expensive than expected, political support might waver. The technology needs to prove itself on realistic timelines to maintain momentum.

Regulatory frameworks barely exist. Who certifies an orbital fuel depot as safe? What happens if a depot fails and creates orbital debris? International agreements need updating to address liability and traffic management issues that didn't exist when space treaties were written. These aren't unsolvable problems, but they're not trivial either.

The development of orbital refueling infrastructure marks a turning point. We're moving from exploration as one-off expeditions to establishing permanent capabilities in space. The difference between Columbus's voyage and the establishment of regular transatlantic shipping. The difference between the first airplane flight and commercial aviation.

Within a decade, spacecraft routinely stopping at orbital depots could be as normal as aircraft refueling at airports. The technology enabling this already exists in component form. What remains is integration, testing, and operational experience. Companies and agencies worldwide are racing toward that goal because they recognize the strategic and economic value.

For those following space exploration, the next few years will be pivotal. Demonstration missions will prove or disprove the technology. Economic models will be validated or revised. The winners in this competition will shape humanity's expansion into the solar system for decades to come.

The orbital gas stations aren't just infrastructure. They're the key that unlocks everything beyond them. Mars bases, asteroid mining, trips to the outer planets. All these ambitious goals depend on solving the mundane problem of fueling spacecraft in orbit. We're remarkably close to cracking that problem, and when we do, the solar system will suddenly feel a lot more accessible.

Just as the first gas stations enabled road trips that transformed societies, these orbital depots will enable journeys that transform humanity's relationship with space. We're not just building fuel tanks in orbit. We're building the foundation for a spacefaring civilization.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

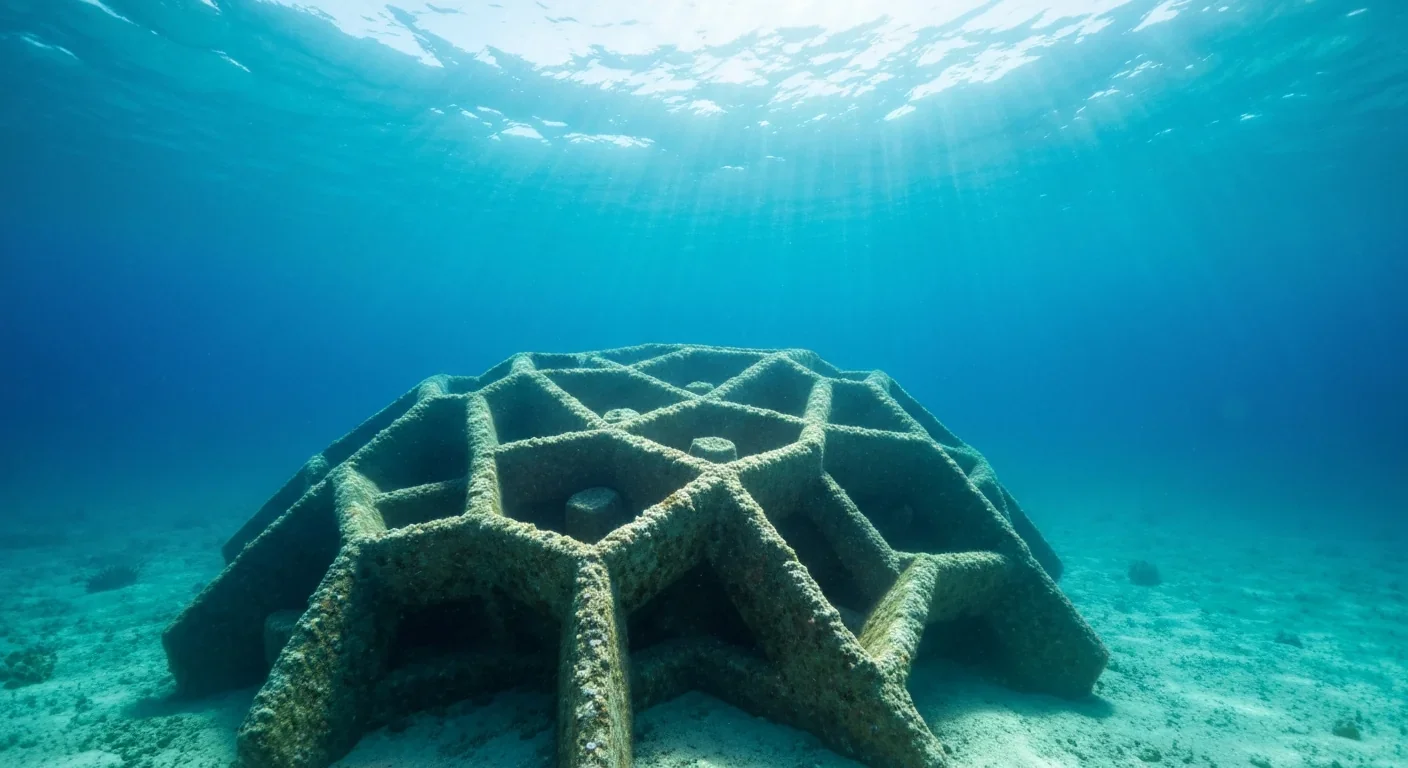

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

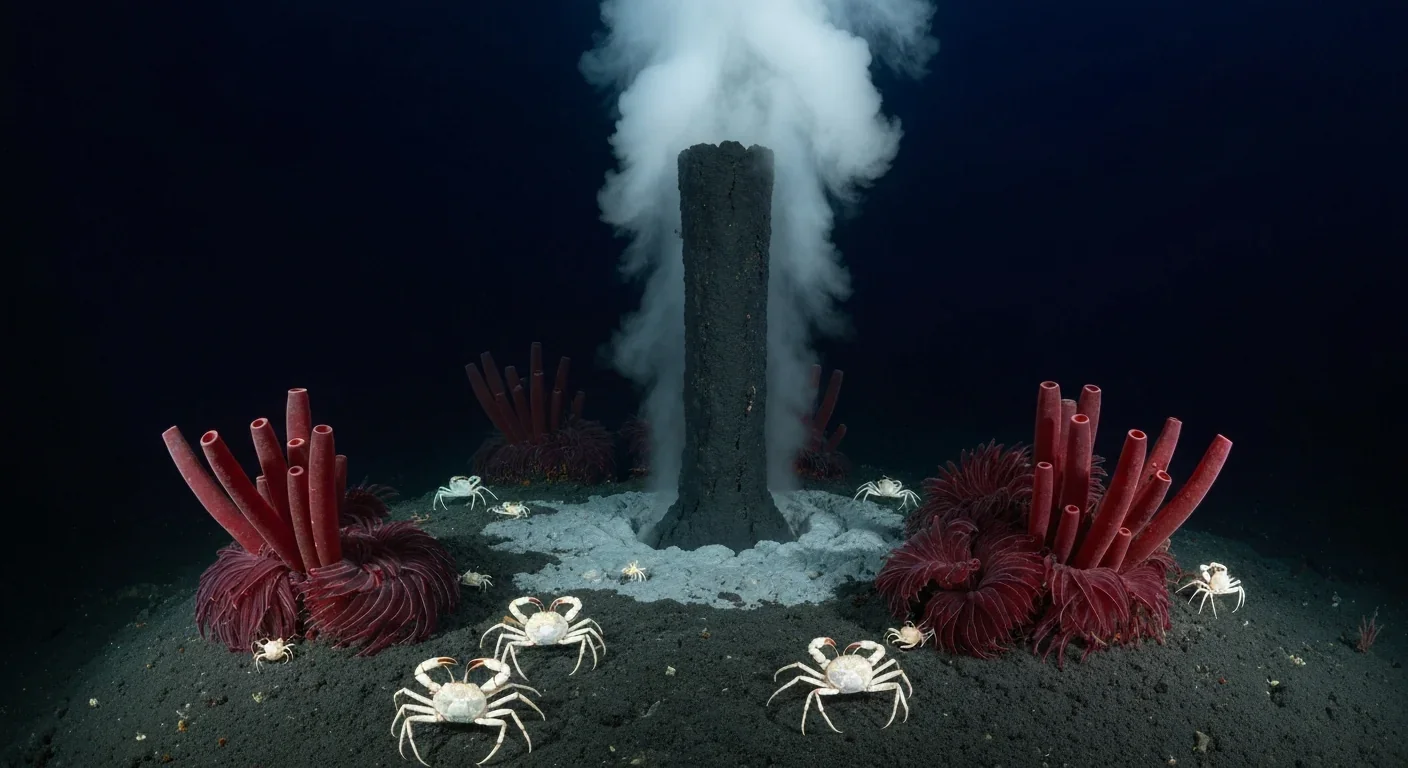

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

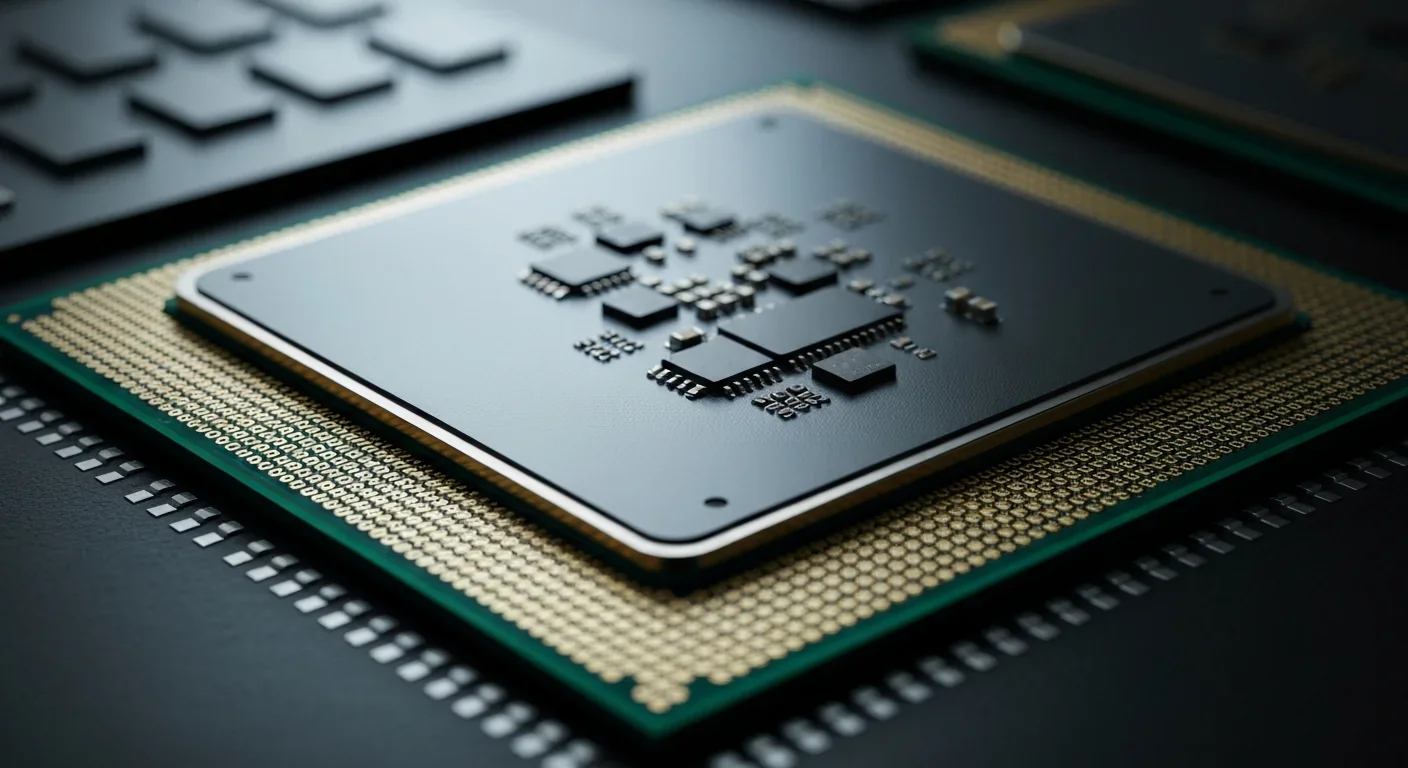

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.